Scalable Printing Systems

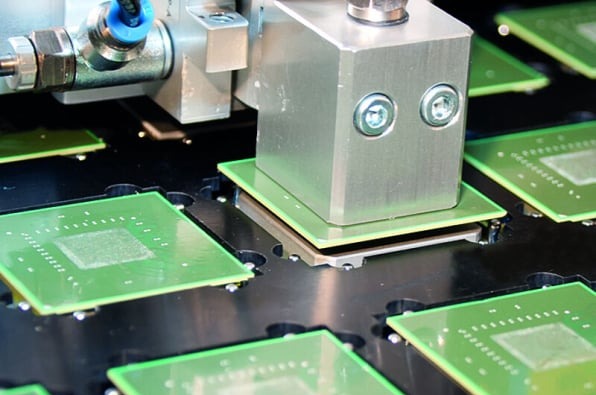

With the EKRA brand we offer scalable printing systems for your electronics production. With our stencil and screen printers, you can apply solder paste to printed circuit boards precisely and with repeatable accuracy. At EKRA, we pay full attention to the details so that you get a custom solution for your production that meets your needs now and in the future. With our broad product portfolio we can offer solutions for every application. From 24/7 to small series production - we accompany you individually with the printer that suits you best.